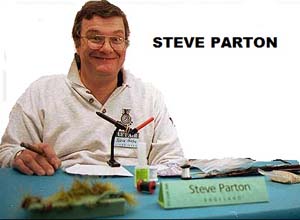

Steve Parton passed away suddenly in 2013 – just a few months after writing this Happy New Year article. His credentials with regard to anything fly fishing stretch across oceans. He was as innovative as he was a character.

He owned Sparton Tackle – making customized rods, fly-fishing gear and fly-tying materials – supplying both the trade and public. He also was responsible for the development the float-tube and made float-tube fishing popular with anglers in the UK and elsewhere.

We edited and excerpted the following article by Parton. He puts a perspective on fly rod costs and pulls no punches.

Graphite Rods: The True Costs

by Steve Parton

[dropcap]T[/dropcap]he important part of any fly rod is the blank . . .

everything that hangs on it is secondary, straight cosmetic or house style in the case of big corporate makers. In the UK you need around £150,000 (current exchange rate is 1 £ = $1.56) to buy the basic plant to roll blanks. And then you need time and money to make the experiments and the mistakes. A year and £20,000 and you should be pretty adequate. It took Harrison and Norwich around those costs and time frames to get going in the last decade. But they are both pretty smart and it might take you rather longer but it is no big deal – maybe 2 years and £40,000 will see you well away.

I don’t make blanks

I just commission them from specialist manufacturers. It has never taken any of them more than 3 stabs to get the blanks I wanted. And that includes most of the work I’ve done with Shakespeare’s using far eastern sources at very long ranges indeed. But I do know almost exactly how to vary actions and therefore fairly precisely how to alter specifications with composites, flag cuts and varied mandrels – that’s why I am a professional consultant – and there aren’t that many of us around. After that it is down to costs because when you have finished the development every fly rod blank I ever saw took less than an hour to make and less than £5 in the most advanced composites currently available.

In the UK any manufacturer can knock out excellent 2 piece 10-foot blanks for £15:00p at base cost. And if you understand production you will not be surprised to realize that to make a sensible profit and pay for the plant, capital and expertise the base price gets tripled so that blank will get sold on at around £45:00p. Any more than that and somebody is pulling somebody else’s leg rather or costs are catastrophically out of control, which can and does happen. Then they wonder why they went bankrupt! You can cut the cost of blanks in two ways – if you buy a lot or make a lot the same then there are some production economies and the more you buy the cheaper they will get.

Cutting costs

The other way of cutting the costs is to proceed to the Far East where the poor sods work for a lot less and when I tell you that I can buy perfectly adequate 10′ AFTM 7/8, 2 and 3 piece fully finished fly rods for just less than £5:00p each from China you will understand just how deadly is cheap labour competition these days. Take a 1,000 set and the blanks I can buy for less than £2:50p – and if I specify the finishes in a corrupt forger’s manner and spend an extra £1:00p per unit, I will willingly bet you couldn’t tell the things from most American or European manufacturing. That is why most of what you think is American or European made isn’t at all.

When you have the blank in your hands it takes well under an hour and a half to fully build and varnish it. And if you are working bulks – the hang on componentry will cost less than £15:00p per rod including handle, reel seat, and rings. Unsurprisingly, snake guides cost a fair bit less than ceramic centered ones – you can save a couple of quid a rod fitting these substandard items at all times – as most Americans do!

And yes, you do have to use a multiplier factor of three to stay in business

At my level of painfully slow hand operation this whole lot basically puts a fully finished rod in my rack for around £90. And I sell it on for £150 but have to manufacture a rodbag and a Cordura tube inside those costs and I can and do do it. It may seem a lot of markup but let me assure you that if you don’t mark up 43% you are going to go bankrupt. And if you are paying London or other Inner City costs for your retail premises it’d better be nearer 80%!

Were I selling into the retail trade the rod would get marked up a further 50% to £225 before it reached a customer. And if I sold it to a Wholesaler who sold it to a retailer then you could add yet another 50% and take the price up to £337:50p. And, of course, if I sold it into the USA then there’d be yet another level of distribution and that’s yet another 50% plus the costs of transportation and maybe even import duty which’d take the price up to around £500.

If you can do sums and think a bit you should by now be fully aware exactly what you are paying for a flyrod, bag and tube and why

Given that less than 3 hours of actual direct labour and probably less than £25:00p in input materials have been used in overall manufacturing it may seem an awful lot – especially if that labour has been employed somewhere where they pay around £1:25p per 10 hour day.

Being very simplistic about things I think I would DEFINITELY HAVE BEEN STUFFED if I paid more than £25 for a Sage / Hardy Build Quality of 10-foot flyrod from the Far East

Most of the cost you have paid has been about levels of distribution, importation, marketing and transportation. Very little has been about manufacturing, research or expert input.

Frankly, there are very few actual fly fishermen involved in manufacturing, development and design these days. Most manufacturers routinely buy the best rods they can find by recommendation. It doesn’t exactly take them a Hell of a long time to drop a couple of different mandrels down the insides – coupled with using a micrometer on the outsides, teaching them precisely what somebody else did. I’d guess at less than half an hour with a specialist. And it takes very much less of a specialist to copy the hang on componentry precisely. This is why you can wander into a (say) Korean rod maker with whatever you want copied and have an actual sample in your hands within a day!

Me, I don’t worry any more, I can’t get more efficient than by selling direct off the factory bench with middlemen out of the equation altogether

But I do get nettled when I know that my customers are being bullshitted into parting with £500 for a far easterner that has been tran-shipped into another country and then into the UK and then moved on down the line with the user price inflating like an automatic lifejacket being fired off.

Little better are the home grown bullshitters who overcharge for far eastern made. But it has to be said that the established professionals at bringing in direct from the Far East do offer far the best value for money because they are in vicious competition with each other.

The writing is probably on the wall for the few of us left who still make in the UK or U. S. I expect to be the last man standing fairly soon in this pathetic country of ours!

Now you know exactly what is involved – you can make your own mind up about what you are going to buy

A word of warning though – there isn’t much loyalty left anywhere in any walk of life these days and brand loyalty is one of the strange anachronisms. It does seem to take forever for a guy who bought a rod from a company that he liked – say 30 years ago – to realize that the game has changed in the interim and that he is no longer a valued customer.

Best wishes and a Happy New Year – 2013