The sweet smell of progress

[dropcap]L[/dropcap]ast spring, East Coast marinas started offering Butanol through Gulf fuels – instead of 10-percent ethanol, its clean air additive (“oxygenate”) will be isobutanol at an EPA-approved concentration of 12.5 percent.

What is it? What does it do? Is it better than ethanol for my engine – the environment?

Biobutanol is an alternative to conventional transportation fuels. The benefits of biobutanol include:

• Higher energy content—Biobutanol’s energy density is 10%–20% lower than gasoline’s energy density. However, biobutanol’s energy content is relatively high among gasoline alternatives.

• Lower ‘reid’ vapor pressure (RVP = measure of the volatility of gasoline) —When compared with ethanol, biobutanol has a lower vapor pressure, which means lower volatility and evaporative emissions.

• Increased energy security—Biobutanol can be produced domestically from a variety of feedstocks, while creating U.S. jobs.

• Fewer emissions—Carbon dioxide captured by growing feedstocks reduces overall greenhouse gas emissions by balancing carbon dioxide released from burning biobutanol.

Stories about isobutanol in Boating showed that advanced biofuel comes from the same feedstocks (plant material) as ethanol, but that it has greater energy density (30 percent higher Btu value), and, most important for our boat engines, it does not absorb moisture or undergo phase separation. It also does not corrode or damage fuel tanks, fuel lines and engine components.

Tests run on waterways and in laboratories over the past five years with the National Marine Manufacturers Association, the American Boat and Yacht Council, the U.S. Department of Energy, the U.S. Coast Guard, Bombardier Recreational Products (BRP) and several other marine engine manufacturers have shown that isobutanol in blends of up to 16.1 percent (B16, now EPA-approved for off-road fuels) are safe. In fact, at the 2015 Miami International Boat Show, BRP offered test rides aboard a 25-foot Crevalle powered by a 300 hp Evinrude G2 running B16.

Biobutanol

Here is how it works.

Butanol, a 4-carbon alcohol (butyl alcohol), is generally used as an industrial solvent in products such as lacquers and enamels. However, it can also be blended with gasoline and used as a transportation fuel. Butanol is commonly produced using fossil fuels, but it can also be produced from biomass, in which case it is called biobutanol. Biobutanol is produced from the same feedstocks as ethanol—corn, sugar beets, and other types of biomass. Biobutanol is a renewable fuel and qualifies under the Renewable Fuel Standard; the category depends on the feedstock used for production.

While there are four isomers of butanol, the most active commercialization work focuses on blending isobutanol with gasoline. There are two Clean Air Act provisions that allow for blending of up to 12.5% biobutanol with gasoline. The fuel quality standard for Biobutanol—ASTM D7862—also allows for a biobutanol blend of up to 12.5% with gasoline. The Octamix waiver allows for a 16% biobutanol blend to be used as a legal fuel equivalent to E10 (10% ethanol, 90% gasoline), however human health effects testing for the fuel is ongoing. It is important to ensure that biobutanol blended with ethanol gasoline combinations do not result in an oxygen content exceeding the Environmental Protection Agency’s limit of 3.7%.

Currently, major refiners cannot sell biobutanol blends for on-road use because it is not registered under 40 CFR (Code of Federal Regulations) Part 79 for companies with revenues exceeding $50 million, as required by the Clean Air Act. However, an additive manufacturer with sales of less than $50 million has sold biobutanol in recent years to specialty markets including marine, jet fuel, and also for conversion to para-xylene, a precursor to a plastic product.

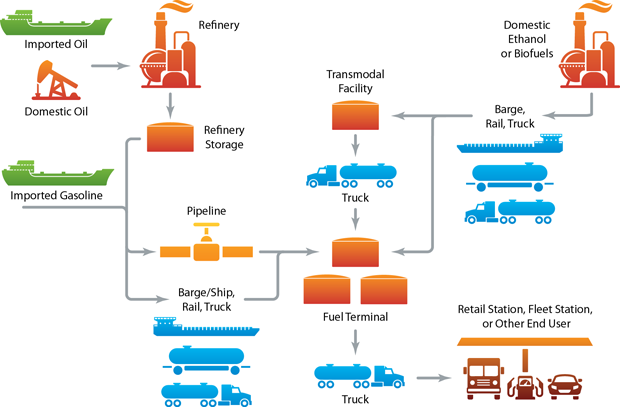

Oak Ridge National Laboratory has researched the compatibility of fueling equipment materials with biobutanol and found that equipment compatible with ethanol blends is compatible with biobutanol. Underwriters Laboratories announced in 2013 that equipment certified under testing subject 87A (for blends above E10) could also retain certification if used with biobutanol. It is anticipated that biobutanol would be distributed by tanker truck and rail, with the potential for transportation in pipelines upon research demonstrating its safety.

Production

The first biobutanol plants are retrofits of existing corn ethanol plants. The fuel is produced through fermentation of corn feedstock and the process is nearly identical to fuel ethanol production from corn. Biobutanol companies produce a range of high-value products, including transportation fuel. Primary co-products of biobutanol plants may include solvents/coatings, plastics, and fibers. Production of these co-products helps biobutanol companies improve economic performance through diversification of product offerings. A challenge for biobutanol is that more ethanol than biobutanol can be produced from a bushel of corn.

Sources: Boating Magazine.com, Capt. Andrew Derr, and Alternative Fuels Data Center.