The May Fly Spring Tide [fly was tied with silk]. Mike Cline extracted from public domain PDF version of above work on the Internet Archive The May Fly – Front piece from Spring-Tide – The Angler and His Friends, George Akerman, London, (1852). Wikipedia commons image.

The thread

By Skip Cement

In his book, A Structured Course in Fly Tying, Steve Hudson devotes two chapters to tying thread.

Kelley Galloup has a YouTube video devoted to fly-tying threads, and Tim Flagler has a short, to-the-point YouTube video made for Orvis on the same subject (Choosing Tying Thread – scroll down for that one-minute video).

Anyone beginning their tying career will immediately notice that thread “size” designations are off-throwing

Threads used to tie flies began with silk, moved to cotton, and were swept out of office by nylon (1935, by Wallace Carothers at DuPont). Nylon was followed by polyester and then monofil thread, which has limited applications, then Kevlar.

Gel Spun came along in the late 1980s via Allied Signal (now Honeywell) and simultaneously in Europe by the Dutch. The Honeywell product is called “Spectra®” and the Dutch version “Dyneema.”

Chris operated Whitetail Fly Tieing Supplies in Ohio until he died in 2014. Whitetail is one of the most comprehensively well-stocked fly-tying shops, perhaps in the world.

Today

Cost:

- Nylon less than $3.50

- Gel Spun less than $5

NOTE: prices are all over the place online: Nylon on-sale for $1.29 and gel Spun for$ 2.19

Nylon and polyester are the overwhelming tying threads of choice because they are cheap and available everywhere; they can be configured round or flat, fuzzy or smooth, and come in a gazillion colors and sizes.

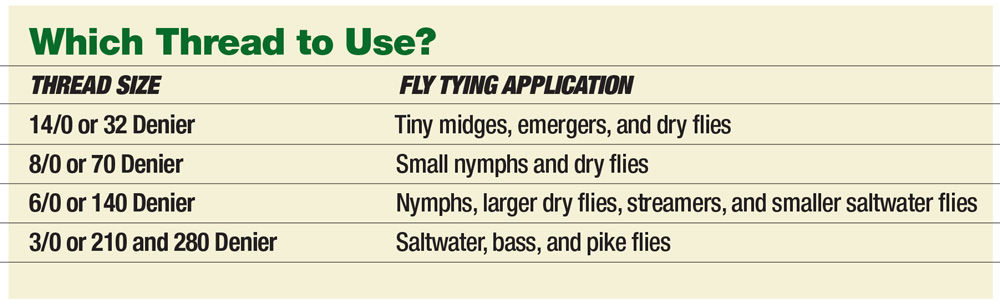

In our tying world, nylon and polyester are inaccurately sized (diameter – manufacturer to manufacturer) and measured by two standards. First, an aught system was invented in the 30s by Danville (the granddaddy of fly-tying threads). It uses zeros (0000) to measure thickness – 12 zeros are thinner than three zeros, or 3/0. Second, the denier weight system invoked by Wapsi (UTC) in the late 80s is an adaptation from the textile industry in which 9000 meters (29527.5-feet) is thread measurement in grams.

If 9,000 meters weighs 120 grams, it is a 120-denier thread. A 70-denier thread is less thick than 140 denier thread. Like the aught system, the denier factor has come to correlate strength.

With gel spun, you can add “thread count” measurement to the aught and denier designations appearing on most labeling. The marked departure with Gel Spun Polyethylene is that it can be almost ten times stronger than its nylon or polyester counterpart of the same denier.

Fly Tyer Magazine article by Porter House.

Waxed or unwaxed?

In some circles, waxed is said to only add to what you don’t need. The advertised advantage of holding on the hook better is a stretch. Aiding in keeping dubbing and other materials better is mentionable, but why buy two green spools, one waxed and one unwaxed? You can buy a lifetime supply of wax for a few dollars.

Rethinking gel spun 50/100/200

GSP is more expensive, not widely available – hard to find even in a good fly shop, and it is not available anywhere close to the number of colors found in nylon/polyester threads. But GSP quickly takes on a Sharpie, so your color choice doesn’t have to be a whole spool of a weird color you had to buy and use just once. Also, with GSP, you can start with white and color as needed, saving a lot of thread as a “useful” inventory. So, no, it’s not hard to tie with.

With GSP, you use fewer wraps because of its strength and fewer spools because you can add Sharpie colors to “white.”

The strength advantage is especially valuable with saltwater flies or anything calling for deer hair or “tight” wraps. In keeping with dollar advantage, not the disadvantage – what demands five turns or more turns with nylon/polyester is very secure with two turns using GSP. It won’t loosen when continually wet or get UV attacked. A fly tied with GSP will last longer, especially tube-tied flies.

Albula Vulpes. Many tropic fly fishers tie all their flies with GSP. Illustration by Thom Glace.

Some professional fly tyers, mostly saltwater tyers are beginning to drift to GSP because it has too many advantages.

- Lay flat no build up.

- No longer colorless.

- Less turns – no more than two.

- No longer prohibitively expensive.

- Readily available.

- The BS about it cutting through materials is a bridge too far. Can it cut through, yes, because you can do chin-ups on the stuff. Who pulls on a thread to 6-pounds?

Gep spun is three to five times stronger than most comparative-size polyester or nylon threads. Also, most white GSP take colored markers well, although more colored GSPs is readily available on the market.

GSP is stronger for its weight than steel and has excellent value. 30 – 50 denier is ideal for tying small flies and a minimum of bulk.

The 75 denier size and the 100 deniers are all-purpose for fresh and saltwater. For use with spun or stacked hair or foam, 200 denier is better to avoid cutting completely through materials.

Not all GSPs are the same

In general, for basic comparisons, 30 denier, about the diameter of 18/0 thread, a breaking strength of 2-pounds 50 denier: about the diameter of 12/0 thread, a breaking strength of 4-pounds. 75 denier: about the diameter of 10/0 thread, breaking strength of about 6-pounds. 100 denier: about the diameter of 7/0 thread, breaking strength of 8-pounds. 200 denier: breaking strength of about 16-pounds.

Veevus, by comparison, 8/0 polyester, breaking strength 3.8-pounds, is about three times as thick as it’s 30 denier GSP, or over twice as thick as the 50D. Kevlar, by comparison, has the same breaking strength for 200 denier GSP thread.

VEEVUS GSP in living color.

One minute fly tying videos by Orvis with Tim Flagler . . .