Wes Seigler is holding a nice GT that didn’t make it past coral heads or deep water and break him off. It was a reel battle.

Three Seigler reels are all you’ll ever need in your lifetime, and they’ll be worth more post hoc

The old and venerable guard of fly reel makers will go kicking and screaming, but what they don’t have has already crossed their borders.

By Skip Clement

[dropcap]B[/dropcap]ut will the unmet technology of these new made only in the USA, selling at twice the current industry price be the next best thing to own? That might be easy to answer if the following features are of interest to your fly fishing outcomes:

- Does repeatability add value to your game?

- Does protection against startup inertia add value to your results?

- Does smooth – not fading in and out as in pulsing on hot runs add value to your efforts?

- Do setting pounds of pressure for the initial strike and runs at different output drag settings [exact] interest you? If those desirable settings of pounds of output drag can be redialed day after day, week after week would that help?

Stepping back in time to look at how a modern reel maker allowed fly fishers to play in the big game fish league

Reels got their first big game fish license when and a Hungarian immigrant refugee tool & die maker and a South Carolina Clothes manufacturing Scion with a passion for big tarpon met in George Hommel’s Worldwide Sportsmen tackle shop [now a Johnny Morris Bass Pro Shop] in Islamorada, Florida, in 1975.

The introduction started fortuitously with a friend of a friend introducing Tibor “Ted” Juracsik [TEE-boar], Tibor Reel Corporation to a man with a REEL need who fished hard and lived in Islamorada [Florida Keys], Florida. His name Billy Pate, a big game fly fisher with worldwide and IGFA record ambitions.

Pate’s want was all about getting a reel that could slow down a tarpon in the 100-pound class without having to palm manage output drag for the duration of a fish fight. Billy Pate and his technical need gave us much of that with the anti-reverse Billy Pate Tarpon Reel, a living tribute to modern reel technology – at the time state-of-the-art [1976].

Tibor.

Tibor made the Billy Pate Tarpon Reel, and it was the first reel that could slow down a big tarpon and not require “palming” as a matter of full-time need – saving a gloved bleeding hand from high-velocity reel rim spin.

Eventually, Ted’s idea of bigger drag washers et al. [plus more], got copied. However, Ted’s marketing, beautiful reel designs, tie in with big game fly fishing guides, making politically astute fishing world alliances, and mounting IGFA record catch statistics [currently 900 or more] for fresh and saltwater fish kept Tibor on the top shelf – almost alone at the top well into his 21st Century retirement.

Then the Walmart fly fishing reels arrived

The technology of Ted’s and others’ drag systems was now well known, old technology, and easily copied without patent infringement. The Chinese and South Koreans had no trouble emulating available reel ‘technology’ [a generous noun calling it technology].

So, easy to copy drag systems with decent builds started becoming available about a decade or more ago for about half the price of the top shelf reels – some as much as a two-third less in the bonefish league.

All but hidden away, like the answer to solving an algorithm of the Rubik’s Cube – Mako Reels

In the early 1990s, after retiring and having come back from a five-month fly fishing reformatory sabbatical of both islands and offshore in New Zealand, I got a late evening call from someone I did not know [no such thing as caller ID]. It was from Jack Charlton. An hour-long conversation about his idea for a new way to make big game fly reels prepped his pitch for seed money to go forward [$25,000] as a partner.

Jake Jordan created a marlin fishery around the performance of this reel.

I was tempted to invest because he hit a chord only serious tarpon and billfishers with world travel creds ever gripped about – talked about; REPEATABILITY – exact output drag throughout the fish fight, and with the next fish, and a week or month later. And a smooth drag – conquering the bugaboo of STARTUP INERTIA.

Startup inertial failure is having preset drag of X-pounds go beyond the preset for a “nanosecond” – go way beyond the prest tension of X to X+4 and snap the tippet. And the elimination of PULSING during a fish fight – drag cycling back and forth from less than the drag setting to more than the drag setting, manifesting flawed drag design behavior with a tippet failure outcome.

I did not invest in Mako reels, regrettably, but Jake Jordan did, and he built a world renown marlin fishery around his investment. Who is Jake Jordan?

Jake Jordan is an icon in the world of fly fishing for tarpon and billfish. He is easy to talk to and willing to do so whether a prince or pauper. Pleasantness marks Jordan, only a few people own that persona – like Lefty Kreh did or now Tom Rosenbauer, Diana Rudolph, Bob Popovics, Andrew Derr, Wanda Taylor, Aaron Adams, Justin Powell, Chuck Kraft, Tim Flagler, Land Tawney, and others of similar note and achievement.

Jake Jordan with a tournament sail and his Mako reel at Casa Viejo Lodge – Capt. Chris Sheeder image. Note tagging while being released.

Jake Jordan, a card-carrying believer in the Mako

Jake Jordan essentially quarterbacked the entire Charlton Reels company into its all but secret, and thriving society of big game fly fishers. The reels stay closeted to this day – sold only to end users – a marketing decision that satisfied Jack Charlton and Jake Jordan.

According to Jake Jordan, any reel good enough to harness these quarter-ton “majestic giant blue marlin” fish is a “machine” not just a reel. The mechanics of these reels are unique, but not widely appreciated [Mako is not available in fly shops], but oddly, there’s a newer get out of jail free technology already procurable and may become readily available in fly shops at a sticker price ceiling not recognizable in the current fly reel world – high.

Who are these folks who only show their faces in MARLIN magazine and on foreign soil docks?

They are a loose fraternity of Da Vinci Code-like dedicated fly anglers who fish solely for sailfish and marlin [the family Istiophoridae]. Swordfish, the sole member of the family Xiphiidae, is not sought after as a “billfish” of game fish status, generally.

Billfish are majestic in the eyes of any beholder – an apex predatory fish characterized by prominent bills [rostra], and by their large size. Some are longer than 15-feet making sailfish and marlins the perfect turn-on for folks that “need” challenges with the added fly fishing only and difficult IGFA rigging rules – a 20-pound tippet limit and other restrictions.

Some anglers fly fish exclusively for billfish and make it a lifetime pursuit. It is said to be an “Ahab” addiction from which no one has ever sought a cure.

Jan Fogt writes about one of the nicest guys in the Ahab tribe, Nick Smith, in Anglers Journal in May of 2107 titled The Natural: “Competitive, curious and obsessive-compulsive, Nick Smith has laser focus once he sets his mind on something, whether it’s catching the most blue and striped marlin on fly or the most sailfish — both of which he’s done numerous times. Smith is driven to succeed, whether he’s building his collection of award-winning muscle cars or running a 23-footer 75 miles to get in on a sailfish feeding frenzy. He’s one of the world’s most dedicated and accomplished sailfishermen — all borne out in time, as he now has 10,000 releases.” Photo by Robert Holland.

There are no known Ahab rehab facilities for those addicted

The man who best described these addicts is one himself [I think], Phil Caputo, a Pulitzer Prize-winning author who found his enjoyed angling Ahab madness in Key West.

This Ahab thing about marlin fishers, in particular, is a dementia Caputo called “The Ahab Complex” – a characterization from his 1988 essay by the same name. Writing: “It’s an obsession to pursue and conquer a monster of the depths regardless of the consequences to one’s bank account, career and family life.”

In “The Ahab Complex” Caputo recalls his life-and-death struggle with a majestic giant blue marlin off the coast of Florida, “. . . whose near half-ton body lit up as if a gigantic light had flashed in the water.”

Let’s talk about groundbreaking made in the USA fly reels

There are only three fly fishing reels, all made by the same USA firm and they have no performance equivalent sold in any fly shop in the world. The new guy on the block seems to have the whole world in his hands – meet Wes Seigler of Seigler Reels.

As the world of Seigler turns so possibly do your big game fish catch stats… all the way down to stocked rainbows. Here are three incomparable reels that will cover every fishing need you’ll ever have in a lifetime of game fish quests on a fly.

Backing up in time. What is being replaced?

The common fly reel brake materials heat up and dry out under sustained friction like cork in select Tibor reels, and plastic braking materials in newer fly reels. Plastics like Rulon, Dulon, and other brand names are all updated derivatives of “Teflon” – discovered by mistake in 1938 in a Dupont lab by a rookie chemist and destined to become necessary for the Manhattan Project, grandma’s muffin tins, car brakes and fly reel brake pads.

These plastics [fluoropolymers] have shorts suits that currently impose a negative on drag performance with heat sink issues and other inhibitors. Some reels are better than others meaning they’ll perform as smooth drags on low settings up to maybe 3- to possibly 5-pounds (a generous number) but not sustainable for a long fish fight or repeatable.

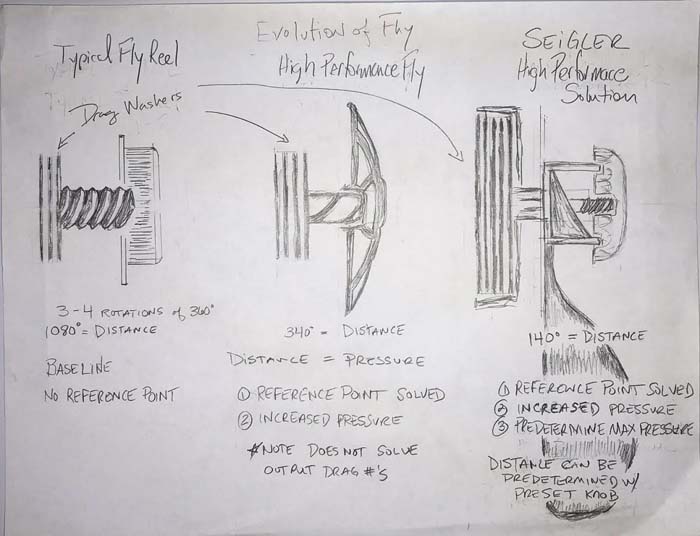

These old school reels knobs crank around the circumference of 360° may be three or more times, so it’s impossible to repeat settings, and nowhere to mark a corresponding inscribe on the reel side plate. It’s just pulling out fly line and guessing what tension is needed.

So, who is this Wes and why doesn’t he go where everyone went

“Gotta be better, not 10%, 30% better – minimum. I will never copy some else’s design. It has to be better, and it has to be mine, and that means it has to be simple,” he says.

Wes is easy going, as easy going as his wife Liz manages him to be, but don’t step on his design grasp, he’s the smartest guy in the room on that score so listening up is a good idea.

He’s never critical of other fly reels, but if you point a brand out, he’ll tell you why it’s okay, not so good or downright misses the performance boat. Like Jake Jordan, he’s not competing. They’ve made a difference – it’s the old school that needs to catch up.

The progression of drag systems as sketched by Wes Seigler a month ago – a coffee break conversation with the maestro.

The Seigler reel has some highly visible design features that make so much sense one wonders why they were not “invented” long ago. Here’s what I mean:

1. Take a look at Wes’s sketch he sent me.

2. You can open a Seigler reel to clean it. He says it’s part of keeping the performance of the reel at full value. Wes says ALL closed systems can have water trapped inside, not necessarily by leakage but by sweating because of temperature changes [condensation we learned about in high school]. In the tropical sun, heating a reel to plus 100°, then in a 75° rapid cool down in a hotel room for the night – repeated for a week and “sweat” has a chance.

Why are Seigler reels so reliable? And why will they outlast [in working order] anything on the market now that could be characterized as old school?

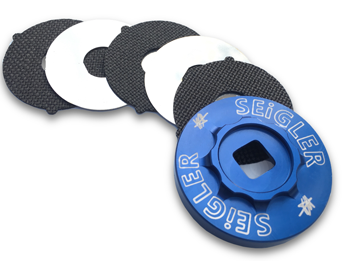

It’s the drag itself. Seigler reels have a clutch system, carbon fiber pads that are always in touch with stainless steel plates, even minimally to avoid free spool backlash – the undoing of many a fly rod when the drag was loosened too far and free-spooled at the gunnels or when the fish swam under the skiff.

This is not organic or plastic – think ceramic and stainless steel.

The wear long term probabilities of ceramic engaging stainless steel and wearing out because of friction in a fly reel application approach never

With Seigler reels simple elements of design are all focused on the anglers comfort, and improved performance like a dovetail reel foot design which is unbreakable and a feature with a real advantage – lessen torque on the arm while casting because of being the lowest rod to reel height of any reel and is replaceable – comes with extra.

Another feature that is so singular to Seigler’s reels is that it makes line wind in one more thing the angler does not have to busy him or herself with while doing the heavy lifting of fighting big fish and bringing it to hand.

The asymmetrical spool design also reduces bearing friction by over 25% and by reducing the torque stress on the shaft while under load allows the line to lay on the downward facing side naturally.

My local fly shop, Seigler reel Cohutta Fishing Company, Cartersville, Georgia. Photo by Andy Bowen.

How do you set up a Seigler Lever Drag Reel?

For example, you’re tarpon fishing using 16-pound tippet, so you do not want to set your max drag at 16-pounds or above 16-pounds. Using 14-pounds as max would be prudent. And with a Seigler Lever Drag Reel, you have another tremendously useful option – the ability to set the strike output drag.

To begin, move the lever forward to the noticeable marker – it’s the strike indicator. Now test with the spring scale just what you want it to be by using the reel knob to make the setting – say 2-pounds. Just keep adjusting the reel knob until you hit 2-pounds of output drag. Now your strike drag output is permanently set. It will not change unless you redo the entire setting process.

Now you want to set the output drag at the maximum output drag that can be applied, which predetermined to be 14-pounds. To start the process move the lever all the way forward – as far as it will go [140°]. Now, using the spring scale and adjusting the reel knob, find where 14-pounds is – set it and forget it, you’re all set — note 1. You can also make additional settings between strike and max or less than strike.

Look where the lever is on the reel. No switching hands, fumbling around for it. It’s right next to your finger – easy to move forward or back.

The Seigler reel settings you just applied will never change unless you change them. However, on the feel-pull line out drag setting “guestimate” which all conventional fly reel drags are limited to, slipping from that setting can occur when long, hard runs stress the drag, so you have to keep adjusting [guessing] at the drag output. That does work, of course, but given the option, I’d lean toward exact — note 2. All Seigler reels are hand made so each reel you own will have different output drags relational to markings on the reel end plate.

BF 11, 12, 13 $1,500 SF 6, 7, 8 $750 MF 9, 10, 11 $1,000

How does a Seigler Lever Drag Reel work? Remember it’s ceramic against stainless steel – not organic and plastic

With the Seigler Lever Drag Fly Reel, the drag plates are pressed directly against the side of the line spool. The drag plate is the size of the side of the spool – distributing pressure across a large surface. This pressure against the spool creates friction, which applies drag to the spool.

When the fish pulls hard enough, the spool slips and pays out line, by pushing the drag lever forward, the drag plate is moved up tighter against the side of the spool. The further the lever is moved forward; the more pressure applied to the spool with the drag plate. By pulling the drag lever back, the tension is relieved. With the lever pulled all of the ways back, the reel will still have minimal contact of a quarter-pound or such so as not to free spool completely.

Seigler Reels

Phone: (757) 271-3113

Email: info@seigler.fish

Address: Seigler Fishing Reels

1352 Taylor Farm Rd Suite #109

Virginia Beach, VA 23453

Mako Reel Corporation

11777 Watertank Road, Unit C

Burlington WA 98233

Email: sales@makoreels.com

Tibor Reel Corporation

255 North Congress Avenue

Delray Beach, FL 33445

Phone: 561-272-0770

Fax: 561-272-0047

Email: custserv@tiborreel.com

Join the discussion One Comment